News

Latest SEP publications

The architectural and engineering firm SEP has successfully designed, built and commissioned a modern and spacious young poultry house for the leading Baltic egg and egg product producer Balticovo.

The new building has been specially designed for outdoor chicken farming, in line with Balticovo’s needs. To achieve this, specific poultry farming technologies and equipment were integrated into the design and construction process. The project was completed in a record time of 12 months.

The new building stands out with sustainable and energy-efficient solutions. It has implemented LED lighting, which significantly reduces electricity consumption, as well as a modern ventilation system, which helps maintain an optimal microclimate and at the same time effectively saves energy.

Special attention has been paid to biosecurity standards to reduce potential disease threats and guarantee the highest level of hygiene. Employees must follow strict disinfection protocols upon entering the facility, while specially designed zoning limits movement between different groups of birds, thereby reducing the risk of infections.

The Latvian Football Federation (LFF) has begun cooperation with the architectural and engineering firm SEP on the development of the concept for the National Football Stadium. The project will be implemented by SEP in collaboration with Regional Projects and UrbanComm, ensuring a comprehensive approach to the development of the stadium and the surrounding area.

To ensure the concept is in line with internationally recognised best practices, SEP will also engage Populous, a world-leading stadium architecture and design firm with experience designing three Olympic stadiums and dozens of iconic football stadiums around the world.

The development of the concept for the national football stadium is a significant step in the development of Latvia's sports infrastructure. The goal of the project is to create a modern stadium that meets international standards, which will promote the development of football in the country and create the opportunity to host international tournaments and sporting events.

Well-planned and sustainable infrastructure will make a significant contribution not only to the development of sports, but also to the urban environment and economy, facilitating the emergence of new opportunities for athletes, fans and the wider community.

The architectural and engineering firm SEP has begun the renovation of the new premises of the Riga International School (ISR) at Skanstes Street 27, which involves redesigning and rebuilding the 3,860 m2 premises in accordance with the requirements of a modern educational institution.

Since the building has previously provided office functions, BHF has selected SEP Office, which will redesign and rebuild the new premises of ISR in accordance with the requirements of the educational institution. The premises will be renovated and reconstructed to meet the requirements of the school - they will have modern classrooms, science rooms, etc., as well as improvements will be made to the accessibility of the facility's environment. Common areas will be modernized, and a separate entrance will be created for tenants on the upper floors, ensuring greater access and comfort for their employees and guests. In addition, a new bus stop for school transport will be installed near the building.

Since construction regulations stipulate higher quality requirements for educational institutions than for office premises, as part of the renovation, a significant redesign of engineering networks and, accordingly, construction will be carried out in the 3,860 m² premises - replacement of electrical wiring, replacement of ventilation and fire safety systems in accordance with the requirements of the educational institution. It is planned that design and construction work in the spacious premises will be completed by May 2025.

Baltic Horizon Fund (BHF) announced in 2024 the conclusion of a lease agreement with Riga International School, which was one of the largest office space lease transactions in Riga last year. This is the first lease of four floors with a total area of 3,860 m2 in the eight-story office building S27, Skanstes Street 27.

The biogas purification and biomethane production plant BOVO GAS, designed and built by the architectural and engineering firm SEP, has received an A+ building energy efficiency certificate.

This certificate certifies:

🔸SEP's high professionalism and competence - our engineers develop modern and technologically innovative solutions for such complex engineering projects as the biogas purification and biomethane production plant under construction

🔸Adherence to sustainability principles – environmentally friendly methods, materials and technologies were used in the design and construction process, which reduce energy consumption and environmental impact.

🔸Excellent project management - such a certificate confirms that all stages of the project - from initial design to implementation - have been carefully thought out and precisely implemented.

🔸Compliance with the highest standards – the office works in accordance with international and local construction and energy efficiency standards.

🔸Understanding customer needs – buildings with an A+ energy efficiency certificate provide significant energy savings, which reduces operating costs in the long term, meeting customer interests and requirements.

Our team continues to expand, and we are happy to announce that a new road design department has joined our existing eight departments of architects and engineers!

The creation of this division marks an important step in our company's growth strategy, allowing us to more effectively address current infrastructure challenges and offer modern, sustainable solutions.

The main areas of activity of the new department include:

🔸Traffic infrastructure design to ensure the creation of safe, functional and modern transport systems;

🔸Development of road and bridge improvement solutions that will help increase the efficiency and safety of the existing infrastructure;

🔸Sustainable mobility planning to promote the development of environmentally friendly and adapted to people's needs.

Our goal is to provide high-quality and innovative solutions that improve both people's daily lives and contribute to sustainable development. We are ready to take on new challenges and, with a professional approach, make a significant contribution to the development of infrastructure on a local and international scale!

The design and construction office SEP, in cooperation with the Union of Latvian Architects, launched a unique and unprecedented initiative - "Architects' Breakfast". This event brought together designers, builders and architects to promote mutual networking, collaboration and a common understanding of the development of the industry.

The widely attended event stood out with the active involvement of participants and gave an opportunity to discuss current industry issues.

Several presentations were held during the event, highlighting industry challenges and possible solutions. Edijs Kupčs, chairman of the board of the Association of Latvian Contractors, outlined the development trends of the construction industry and pointed out the need to improve regulatory standards. Olegs Umanskis, commercial director of SEP, shared his experience on the use of artificial intelligence in design and its future perspectives. Board member of the Association of Latvian Architects' Offices Anda Kursiša spoke about the problems of the industry and the possibilities for its improvement in her presentation.

The participants of the event expressed their desire to hold this type of meeting regularly in order to further strengthen the dialogue and development of industry professionals. "Architects' breakfast" also became a platform where participants could introduce their services to others, look for new cooperation partners and make contacts. The goal of the event – to promote the exchange of opinions and mutual cooperation – was achieved with success.

SEP has completed the design works for the industrial park, which will be located in Madona county municipality.

It envisages three new hangar-type production buildings, which will be built in a previously undeveloped, degraded industrial area in the city of Madona. After the completion of the construction works, the buildings will be leased to local entrepreneurs, thus promoting business development in the Madona region.

Some facts about the designed buildings in the industrial park:

🔸the area of each building is 1000 m2

🔸a shed (area 500m2) was planned for each building, which will serve as an open-type warehouse

🔸the buildings will consist of a production area and an office block, where an employee lounge with changing rooms, a sanitary unit and office space for employees were planned.

The buildings will be provided with external water and sewage connections to the main networks according to the natural conditions, electricity supply from the nearby substation, and all necessary internal networks and communications for the functioning of the building:

🔸 water supply and sewerage

🔸electricity and lighting

🔸heating and ventilation

🔸fire extinguishing automatic systems.

The Madonas industrial park will be implemented in five phases - each building with adjacent networks in a separate phase, as well as the asphalting works of the adjacent free area (9831 m2) will be implemented in two phases.

SEP commercial director Oļeg Umanski, together with other representatives of 60 Latvian companies, had the opportunity to participate in the largest Latvian business delegation trip to the USA, organized by the Latvian Investment and Development Agency (LIAA) and the Ministry of Economy.

This trip provided a unique opportunity to demonstrate SEP's experience in construction and design, as well as to tell about SEP's unique biogas and biomethane production solutions, while providing an opportunity to form new partnerships and find investment opportunities in the US market.

The destinations of the trip were significant - San Francisco and Silicon Valley are a global technology center that offers unlimited opportunities for innovation; Denver stands out for its growing technology and energy sector, while Houston, as the energy capital of the US, is an ideal place where SEP could form partnerships with representatives of the energy sector.

SEP Commercial Director Olegs Umanskis used a unique opportunity to discuss biogas production opportunities in the US with global energy sector leaders. SEP has already received positive feedback and interest in its biogas production technologies.

Of particular note was the reception organized by the Latvian Investment and Development Agency (LIAA) in San Francisco, which was attended by Latvian President Edgars Rinkēvičs, California Senator Josh Newman and other representatives of the state of California.

SEP has successfully completed the modernization of the "EggEnergy" biogas production plant, which allowed the station to increase the volume of biogas produced by 50%. The plant has been commissioned and is currently working at full capacity.

Elements created as part of the modernization include:

- additional hydrolysis tank with biofilter for odor removal,

- two fermentation tanks with pumping station,

- new pre-treatment equipment for sulfur and ammonia purification,

- substrate and gas transmission networks,

- heat supply networks for heating fermentation tanks.

All solutions included in the modernization were carefully designed and integrated into the existing infrastructure of the station. These improvements allow the plant to produce up to 18 million cubic meters of biogas per year.

The biogas produced by "EggEnergy" is supplied to the biomethane production plant "BovoGas", and the increased volume of biogas almost doubles the total amount of biomethane fed into the gas network, reaching 190 MWh per day.

"EggEnergy" is one of the most unique biogas stations in the world, because biogas is produced only from chicken manure. The high ammonia and sulfur content of chicken manure makes biogas production a difficult engineering challenge, making the technology developed and implemented by SEP an attractive solution for poultry farms worldwide. With this project, SEP proves its ability to develop innovations that not only improve production efficiency, but also promote the use of sustainable energy sources.

SEP has completed the construction of the unique “Bovogas” biogas plant - it purifies biogas into biomethane, a natural gas equivalent. Moreover, it’s significant that “Balticovo” has partnered with Latvia’s natural gas transmission and storage system operator, AS “Conexus Baltic Grid,” and the natural gas distribution system operator, “GASO,” to create the first connection in Latvia through which the biomethane produced by “Bovogas” is injected into the interconnected gas system.

The connection of “Bovogas” to the interconnected gas system has been challenging due to it being the first project of its kind in Latvia, as well as the high-quality and safety requirements for biomethane and engineering systems. Engineering challenges relate to achieving the final result - for the valve to open to the interconnected gas system, “Bovogas” purified biomethane must reach very high purity and specific quality with minimal allowable concentration deviations. To achieve the required quality level, a perfect system is needed, including biogas cooling, drying, compression, and purification functions, as well as biomethane compression and emission gas venting functions. Currently, “Bovogas” continuously purifies and injects up to 16 bar compressed biomethane into the network 24/7!

A group of auditors from SIA “Bureau Veritas Latvia” has completed the external recertification audit of SEP. During the audit, the auditors reviewed SEP's integrated management systems, namely, quality, environmental management, occupational health, and safety compliance with the requirements of the relevant international standards:

- ISO 9001 - Quality Management

- ISO 14001 - Environmental Management

- ISO 45001 - Occupational Health and Safety Management Systems

According to the final report from the auditors, SEP has successfully passed the recertification audit and is certified for three years in the following sectors:

- Water supply

- Heating supply

- Electricity supply

- Gas supply facilities

- Biogas and biomethane production facilities

as well as the design and design management services of other industrial and civil construction projects.

SEP concluded a contract with the Madona municipality for the design of hangar-type production buildings at 77 Saules Street in Madona.

As part of the construction project, three new hangar-type production buildings are planned to be designed in a previously unbuilt, degraded industrial development area in the city of Madona. The area of each building is 1000 m2, and each building will have a canopy (area 500m2), which will serve as an open-type warehouse.

The buildings consist of a production area and an office block, which includes employee rest areas with changing rooms, sanitary facilities, and office space for employees.

The buildings will be provided with external water and sewage connections to the main networks according to the natural conditions, electricity supply from the nearby substation, and all necessary internal networks and communications for the functioning of the building:

- Water supply and sewerage,

- electrical supply and lighting,

- heating and ventilation,

- fire alarm systems.

The buildings will be surrounded by landscaped areas, parking lots - an asphalted area with a total area of 10,000 m2, and in the right part of the land plot, an asphalted area will be provided with a total area of

13 100 m2.

The construction project is planned to be implemented in five stages, and after the completion of construction works, the Client will lease the buildings to local entrepreneurs, thereby promoting business development in the Madona municipality.

SEP gathers industry professionals with the Union of Architects

The design and construction office SEP, in cooperation with the Union of Latvian Architects, launched a unique and unprecedented initiative - "Architects' Breakfast". This event brought together designers, builders and architects to promote mutual networking, collaboration and a common understanding of the development of the industry. The widely attended event stood out with the active involvement of participants and gave an opportunity to discuss current industry issues.

Several presentations were held during the event, highlighting industry challenges and possible solutions. Edijs Kupčs, chairman of the board of the Association of Latvian Contractors, outlined the development trends of the construction industry and pointed out the need to improve regulatory standards. Olegs Umanskis, commercial director of SEP, shared his experience on the use of artificial intelligence in design and its future perspectives. Board member of the Association of Latvian Architects' Offices Anda Kursiša spoke about the problems of the industry and the possibilities for its improvement in her presentation.

The participants of the event expressed their desire to hold this type of meeting regularly in order to further strengthen the dialogue and development of industry professionals. "Architects' breakfast" also became a platform where participants could introduce their services to others, look for new cooperation partners and make contacts. The goal of the event – to promote the exchange of opinions and mutual cooperation – was achieved with success.

This biomethane plant was specifically developed and built for Balticovo, the largest egg and egg product producer in Northern Europe. It's a unique project because, for the first time in Latvia, a connection has been established in collaboration with Latvia's natural gas transmission and storage operator, AS Conexus Baltic Grid, and the natural gas distribution system operator, GASO, to introduce the biomethane produced by Bovogas into the interconnected gas system. This is a significant event in the development of the biogas and biomethane industry in Latvia.

It's worth noting that SEP's engineering challenges were related to high standards of quality and safety - to open the valve to the shared gas network, the purified biomethane from "Bovogas" must meet very high purity and specific quality requirements, with minimal allowable concentration deviations. Achieving this quality requires a perfect system, including biogas cooling, drying, compression, and purification, as well as biomethane compression and exhaust gas disposal.

It should be noted that "Bovogas" will be able to produce and introduce more biomethane into the gas pipeline in a year than all households in the Bauska region consume in a year!

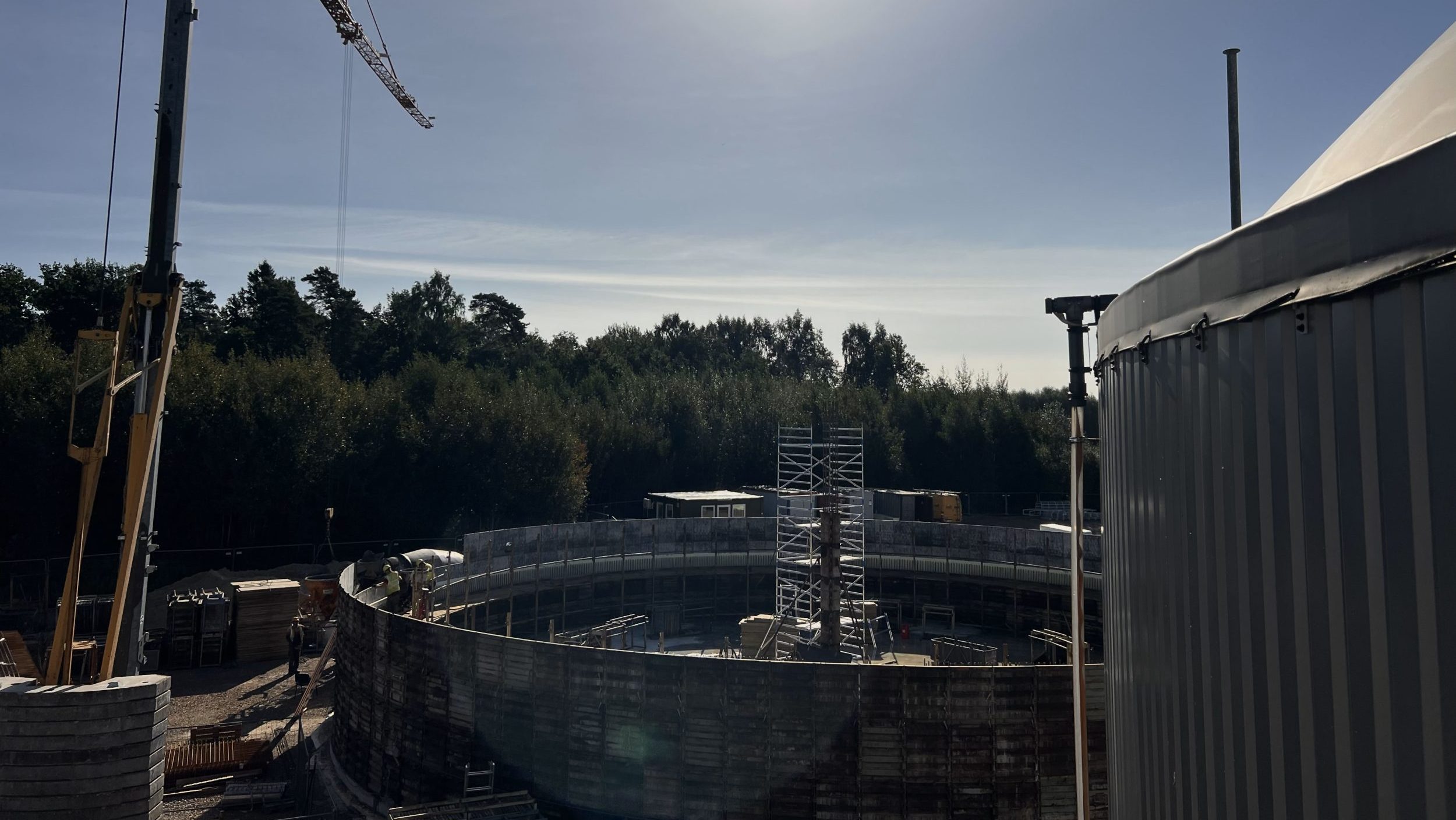

SEP has an opportunity to boast - the biogas purification plant BOVO GAS has been put into operation.

The total area of the factory building is 1850 m2, but its construction started in April 2023. The factory premises have two biogas purification lines with a capacity of 1000 m3 of biogas per hour, and from this volume, the final product of 55-70% is biomethane! To ensure all technological processes, the factory also has a cooling circuit, a nitrogen and oxygen circuit, as well as a heat exchanger circuit with a boiler. To keep the building and production process safe, BOVO GAS has relay protection, gas and fire alarm signaling (security system), as well as a communication network. Automation is used in all building and equipment electronics.

As for technological equipment, adsorption technology is used in the biogas purification process. A very modern gas analyzer - chromatograph is installed at the BOVO GAS plant, which checks the quality of purified methane before injection into the GASO network.

Also, a 1.8 km long gas pipeline BOVOGAS and a biogas production plant have been built EGG ENERGY - Iecava, Latvia.

Design and construction office "SEP" is launching a new and ambitious project in the field of commercial and cargo transport maintenance. Namely, "SEP" office has started designing industrial premises for "Skuba Latvija" truck maintenance service.

The total area of the industrial premises designed by "SEP" is 7000m2 in an amount that is a significant scale for industrial projects of this type in Latvia.

Taking into account that after the completion of the construction in the premises "Skuba Latvija" will provide the maintenance of cargo and commercial transport service and the sale of spare parts, the design of the premises promises to be challenging for the designers of "SEP" due to the technological requirements.

During the design process, "SEP" designers need to foresee the integration of complex service equipment in the premises. It includes modern technological, automation and environmental solutions that meet the highest industry standards.

We are happy to announce that SEP has started an exciting and productive cooperation with one of Latvia's leading architectural offices - "Kvites Architects"!

This collaboration gives SEP a unique opportunity to combine the office's expertise and creative vision with Kvites Architects to create aesthetically pleasing and innovative and outstanding construction projects.

We are sure that the cooperation between SEP and "Kvites Architects" will be creative and innovative, in which the teams of their companies will complement each other!

Another step in the construction of the Bovo Gas biomethane plant completed! All necessary equipment for biogas treatment has been supplied and installed, and SEP is continuing the construction of the plant building itself.

Introducing our new look. As the company develops and grows, we also improve and modernize our new look!

We would like to say a big thank you to our colleagues, employees and customers - without you, SEP would not exist!

SEP has started work on the modernization of the EGG ENERGY biogas cogeneration plant.

Currently, the modernization of the production facility led by SEP is underway, as a result of which EGG ENERGY will be able to increase the production capacity even by 50%, reaching the volume of 3 MW

Expanding its activity, A/S "Balticovo" in cooperation with the design and engineering office "SEP" has started work on the construction of a new shelter for young birds in Iecava, Bauska county.

SEP starts the construction works of the biomethane and liquefied carbon dioxide plant project in Iecava.

The Latvian design and engineering office SEP (A/S "Siltumelektroprojekts") has signed an agreement with JSC "Putnu fabrika Ķekava" for the design of a biomethane production plant.

SEP starts the construction works of the biomethane and liquefied carbon dioxide plant project in Iecava.

In the project created in cooperation with Balticovo, biogas will be purified to biomethane, which is already a changing alternative to natural gas in the energy sector. In the new "BovoGas" station, it is planned to produce 100 GWh of biomethane per year.