Design

Design and architecture

DESIGN YOUR FUTURE WITH SEP

SEP's knowledge and experience, architectural and engineering resources will help you implement a project of any scale and complexity. With a team of more than 50 engineers representing 8 different engineering departments, SEP offers comprehensive solutions in design and construction.

SEP’s standards ensure that its clients get a high-quality end design product that is fully implemented in a BIM environment. BIM has been successfully used to develop more than 30 projects in the USA, Scandinavia, and the Baltic States.

Design

Full design cycle

Our in-house architects, engineers, and designers provide a full design cycle from idea and technical design development to author supervision.

High-quality and professional design provides functional, aesthetic and sustainable solutions that meet the client's needs and comply with regulatory standards, while optimizing resources and promoting the successful implementation of the project.

Main phases of the design cycle

Feasibility study and planning

Initial design (concept)

Technical design

Project coordination

Preparation of documentation package

Project implementation and monitoring

Project handover and operation

Design services

SEP design services

Architecture and master planning

- Design of buildings and territories

- Development plans and master planning solutions

- Ensuring compliance with regulatory enactments

Building structures

- Design of load-bearing structures

- Structural analysis and strength calculations

- Non-standard construction solutions and innovations

Road design

- Traffic infrastructure design

- Road and bridge improvement solutions

- Planning for sustainable mobility

Electrical engineering

- Designing of power supply systems

- Lighting and energy efficiency solutions

- Integration of automation and control systems

Automation, low currents and communication networks

- Automation and control systems design

- Low current and security system solutions

- Design and implementation of communication networks

Heating, ventilation and climate control systems

- Designing energy-efficient HVAC systems

- Climate control and automation solutions

- Optimization of systems sustainability

Water supply and sewerage

- Design of water supply and wastewater systems

- Sustainable and environmentally friendly technologies

- Stormwater management solutions

Technology integration

- Development of innovative technical solutions

- Ensuring system compatibility

- Design and implementation support

BIM (Building Information Modeling)

- Development and coordination of digital models

- Resource optimization and process planning

- Data management and facilitating collaboration

Our clients

CURRENT PROJECTS

BIM technologies

BIM - the industry standard

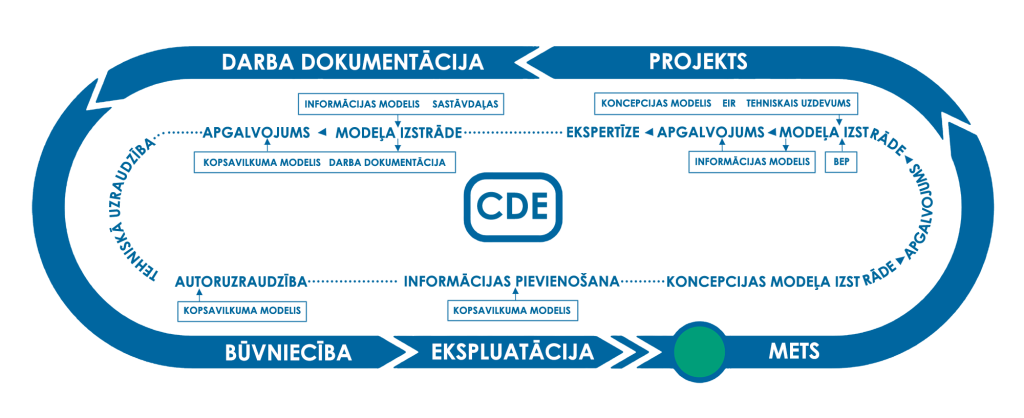

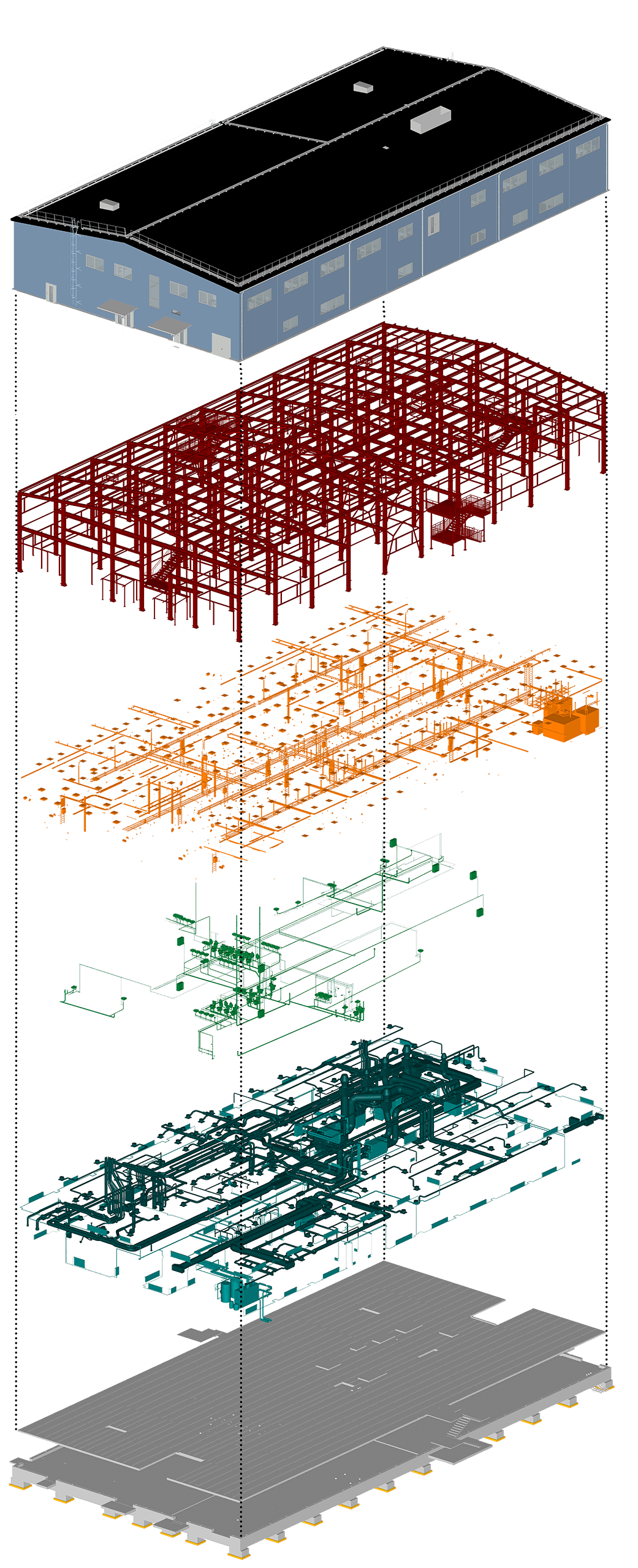

BIM (Building Information Modeling) is a digital process of designing a building or a piece of infrastructure that involves creating and managing all building information throughout its life cycle, from the initial design plan to the structure’s normal operation.

The result of this process is a building information model (BIM model), namely 3D geometry with additional attributes. It should be emphasized that BIM is a process, while the BIM model is its result.

Advantages of BIM

BIM TECHNOLOGIES: KEY BENEFITS

We have used this technology in more than 30 completed projects.

The BIM technology encompasses all field-specific information, for architectural, structural, electrical, heating, ventilation, water, power and other systems.

This allows our designers, engineers, and other involved professionals to combine their work into one central information model, and the client to see the project digitally.

Design quality

Advantages of BIM

More efficient planning and utilization of resources, for savings in time and money

More focused and detailed information about the structure, for more accurate calculations and analysis

Better cooperation and coordination among designers, engineers, and other people involved, with a shared data model

Ability to visualise and assess the appearance and operation of a structure before it is physically built

Ability to eliminate problems and conflicts at the design stage, reducing the need for alterations, and the associated costs, during construction

Better cooperation and coordination among designers, engineers, and other people involved, with a shared data model

More efficient planning and utilization of resources, for savings in time and money

Ability to visualise and assess the appearance and operation of a structure before it is physically built

More focused and detailed information about the structure, for more accurate calculations and analysis

Ability to eliminate problems and conflicts at the design stage, reducing the need for alterations, and the associated costs, during construction

Design quality

Quality certificates

SEP has been obtaining internationally recognized certificates certifying the quality standards of the integrated management system for several years in a row.

ISO 9001:2015 – certifies the office's ability to ensure high quality of design and construction in compliance with internationally recognized quality management standards.

ISO 14001:2015 – certifies the company's commitment and ability to effectively manage environmental issues, complying with international standards and taking measures for environmental protection and sustainable operations.

ISO 45001:2018 – certifies that the office provides its employees with internationally recognized health and safety standards.

Frequently asked questions

Find answers to your questions

What regulations and standards must be followed when constructing an industrial building?

When designing industrial buildings, Latvian Building Codes (LBN), European Union standardization requirements (for example, EN 1990–1999, which covers building structures), as well as industry-specific regulations, such as fire safety and occupational safety requirements, must be followed.

What are the main steps in the design process for industrial construction?

The main steps are: defining the initial idea and requirements, site analysis, concept development, preparation of technical documentation, project coordination with authorities, detailed planning, and, finally, supervision of the author during the project implementation.

Is it possible to optimize project costs without losing quality?

Yes, costs can be optimized by choosing more efficient materials, modular construction, or technologies that speed up construction. It is also important to make accurate calculations in advance to avoid unnecessary expenses at later stages.

What information is required from the client at the beginning of the design process?

Information is required about the functionality of the facility, its dimensions, special requirements (such as fire safety or logistics flow), budget, site characteristics (topography, soil composition), and the client's desired timeline.

How is the project's compliance with safety and sustainability requirements ensured?

Safety and sustainability are ensured by performing engineering calculations, choosing certified materials, designing energy-efficient systems, and complying with regulations relating to the environment and resource use.

What is the project implementation period from idea to commissioning?

The deadline depends on the size and complexity of the project. On average, it can take from 6 months to 2 years, including design, coordination and construction.

How is the project coordinated with state and local government institutions?

How is the project coordinated with state and local government institutions?

How will the project implementation be monitored during construction?

The designer supervises the author to ensure that construction is carried out in accordance with the project documentation. This includes regular site inspections and communication with the builders.